News

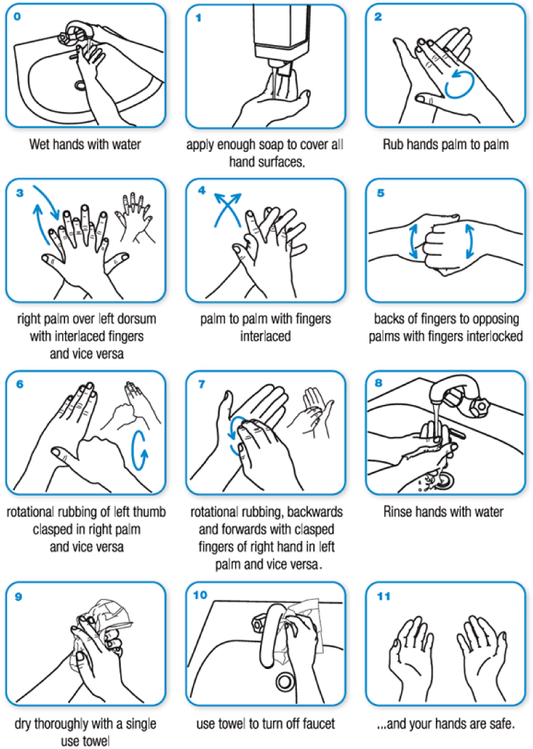

Lab and venue hygiene best practices

Our Coffee Quality Institute team was asked to develop best practices enabling attendees to feel confident in the sanitation procedures of our venues. The official CQI release is linked here...

Lab and venue hygiene best practices

Our Coffee Quality Institute team was asked to develop best practices enabling attendees to feel confident in the sanitation procedures of our venues. The official CQI release is linked here...

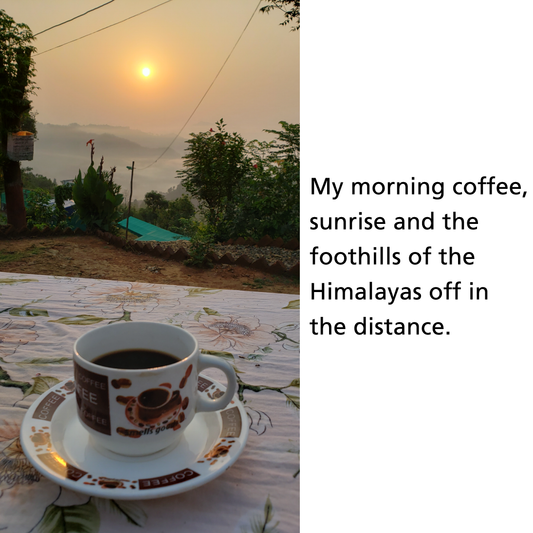

The International Trade Center visits the Acade...

This article was originally publish in March of 2020 in the International Trade Center's online news addition. Nepal is known more for its mountains than its coffee but ITC’s acting...

The International Trade Center visits the Acade...

This article was originally publish in March of 2020 in the International Trade Center's online news addition. Nepal is known more for its mountains than its coffee but ITC’s acting...

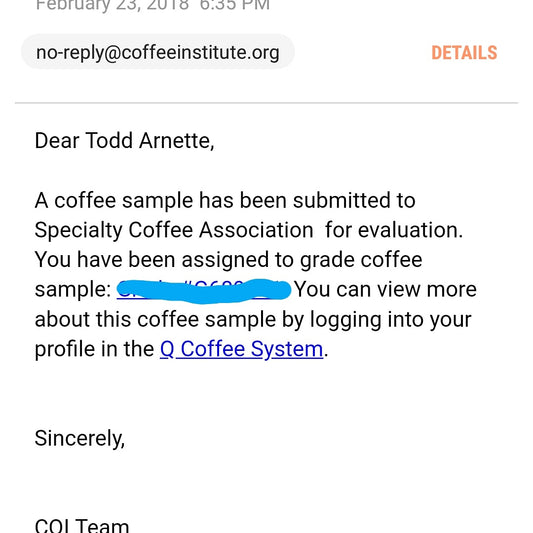

Adventures In Coffee Quality

By: CQI Consultant Todd Arnette, Academy of Coffee Excellence In my years since becoming a Q Grader and Q Instructor for Coffee Quality Institute (CQI) I have had the great fortune to...

Adventures In Coffee Quality

By: CQI Consultant Todd Arnette, Academy of Coffee Excellence In my years since becoming a Q Grader and Q Instructor for Coffee Quality Institute (CQI) I have had the great fortune to...

Why cupping should be taken seriously?

When cupping we follow a protocol so that we can have the same experience with the coffee and be consistent. As cupping instructors, we also tell cuppers to be honest...

Why cupping should be taken seriously?

When cupping we follow a protocol so that we can have the same experience with the coffee and be consistent. As cupping instructors, we also tell cuppers to be honest...